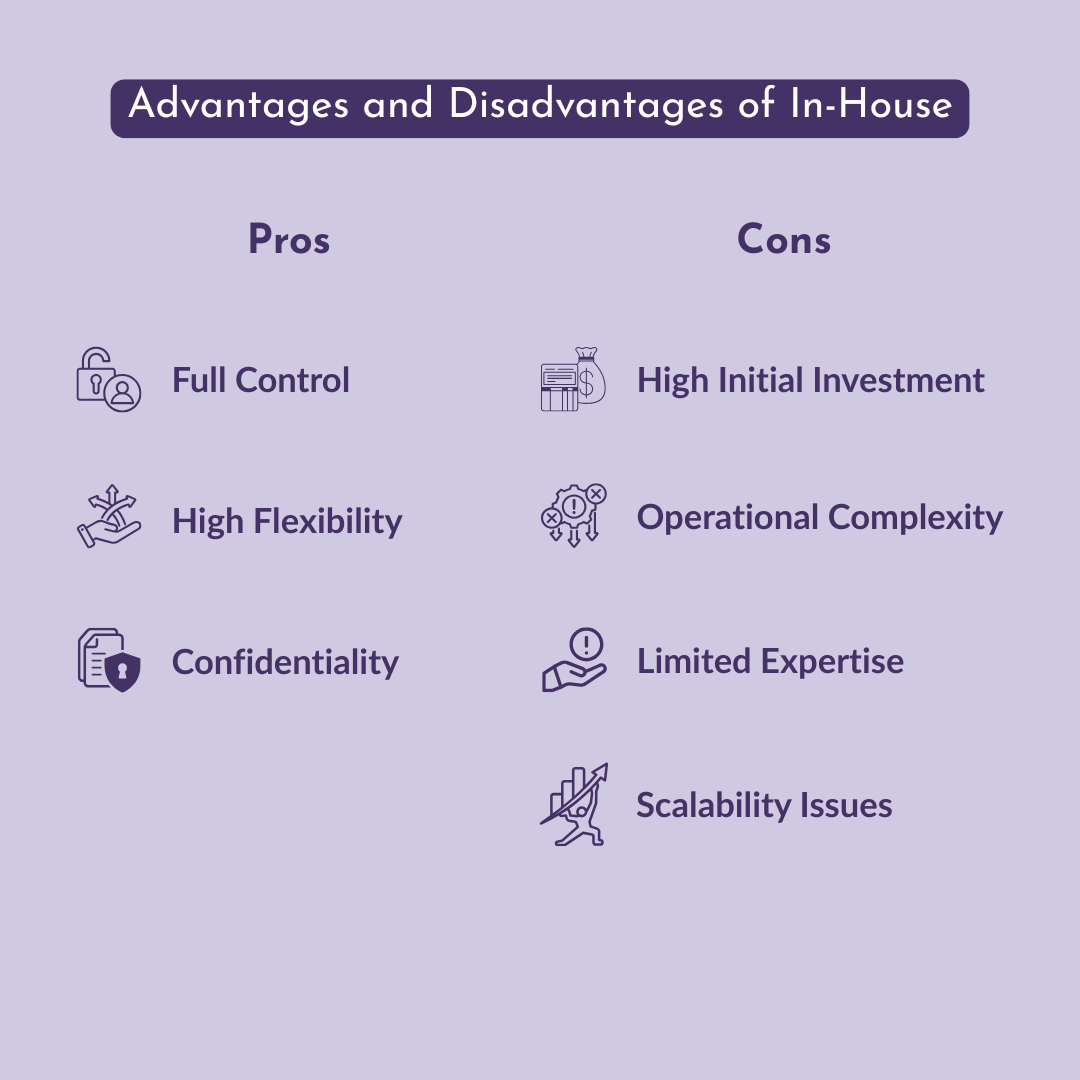

Hidden Cost of In-house Production:

High Cost:

Starting production from scratch not only involves purchasing equipment but also entails finding the proper premises, setting up the infrastructure, and complying with regulations.

These huge expenses can strain small businesses' financial resources, especially if the budget is limited.

| Felt and Yarn has 3 well-maintained production units and 3 warehouses & QC absorbing these costs for you.

Production complexities

When volumes are high, production scheduling must be efficiently planned to avoid a bottleneck.

Initially starting, it can be challenging to accommodate the internal team, which can often lead to a loss of quality, delays in work and loss of sales.

| Felt and Yarn has 100k+ monthly production capacity and can handle a large volume of orders.

Expertise and Skilled Artisans

Hiring can come with a flight risk in case of in-house production. Moreover, employees expect benefits, training, and skill development, which are resource-intensive.

On top of it, dealing with turnover, well-maintained facilities, and other compliances will require significant investments.

| Felt and Yarn has over 2000 employees, all well managed under one production house.

Logistics

Logistics is one of the most underestimated complexities in in-house production. Managing packaging, documentation, customs compliance, and last-mile delivery adds a significant operational burden.

Delays in customs, mislabeling, or inadequate tracking can damage client relationships and brand credibility.

| Felt and Yarn has 40K+ orders delivered to 75+ countries, offering full logistics support and real-time tracking.